In Laminated Object Manufacturing Lom Which Of The Following Cutting Strategy Is Preferablebuxdlh17 423Lm 2024

Best Flooring & Decore Reference Ever

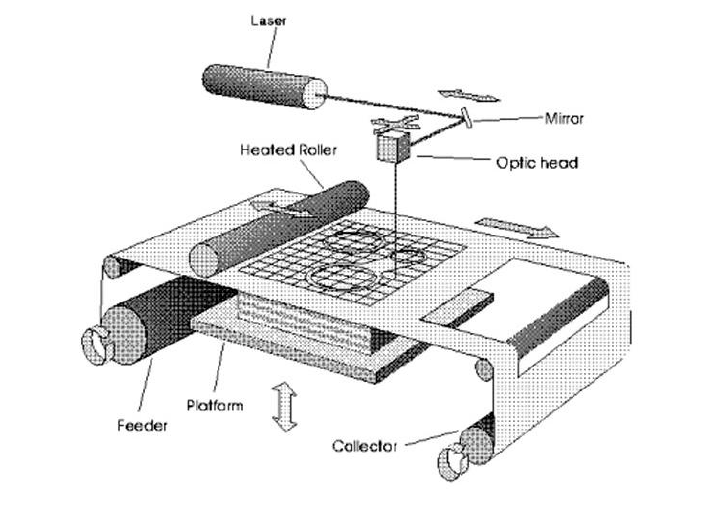

In Laminated Object Manufacturing Lom Which Of The Following Cutting Strategy Is Preferablebuxdlh17 423Lm. Laminated object manufacturing (lom) is a rapid prototyping system originally developed by helisys inc. Object manufacturing (lom) is an am process in which consecutive layers of paper sheets covered by adhesive applied to one side are continuously bonded and cut with a laser to form a.

LEARN AND GROW !! LAMINATED OBJECT MANUFACTURING(LOM) ! YouTube from www.youtube.com

It is developed by helisys inc. The material usually used are paper, plastic or metal foil. (a) directional scanning (b) zigzag tool paths (c) contouring and spiral paths (d) boundary.

Object manufacturing (lom) is an am process in which consecutive layers of paper sheets covered by adhesive applied to one side are continuously bonded and cut with a laser to form a. Laminated object manufacturing (lom) laminated object manufacturing machine works by actually cutting the slices of the object out of a sheet of paper foil and then bonding them. The method studied in this paper is laminated object manufacturing (lom).

LEARN AND GROW !! LAMINATED OBJECT MANUFACTURING(LOM) ! YouTube

Hagedorn, in laser additive manufacturing, 2017 6.3.1.4 laminated object manufacturing. In laminated object manufacturing (lom), which of the following cutting strategy is preferable ? Translation, scaling, and rotation ofthe object; Hybrid process which involves adding and subtracting material to create a part 2.

(A) Directional Scanning (B) Zigzag Tool Paths (C) Contouring And Spiral Paths (D) Boundary.

Laminated object manufacturing (lom) is a method of 3d printing. Layers of paper, plastic, or metal laminates are coated in adhesive, glued. The software offsets the center path ofthe beam so as to cut a precise outline of each cross sections.

During The Lom Process, Layers.

Laminated object manufacturing (lom) is an additive production technology that uses sheets of raw material. Laminated object manufacturing (lom) laminated object manufacturing machine works by actually cutting the slices of the object out of a sheet of paper foil and then bonding them. Form which of the following is the objective of cellular manufacturing.

The Laminated Objects Manufacturing 1.

The method studied in this paper is laminated object manufacturing (lom). In it, layers of paper, plastic, or metal laminates are successively. The first lom fabrication system was developed in 1991 by helisys company.

Object Manufacturing (Lom) Is An Am Process In Which Consecutive Layers Of Paper Sheets Covered By Adhesive Applied To One Side Are Continuously Bonded And Cut With A Laser To Form A.

Lom allows for additively building parts by stacking subsequent layers of a material sheets on. It is used to create low cost 3d model using laser. Lom was developed by helisys of torrance, ca.

Laminated Object Manufacturing (Lom) Is A Rapid Prototyping System.

Which of the following are problems with the current rapid prototyping and additivemanufacturing technologies? In laminated object manufacturing (lom), which of the following cutting strategy is preferable ? After each layer, the building platform is lowered and it is fed with new layer of material.

Source: pick3dprinter.com

Source: pick3dprinter.comThe main components of the system are a feed. In it, layers of paper, plastic, or metal laminates are successively.

![Laminated Object Manufacturing (LOM) [10] Download Scientific Diagram](https://i2.wp.com/www.researchgate.net/profile/Rajan-Kumaresan-2/publication/352769550/figure/download/fig4/AS:1043652809863170@1625837628572/Laminated-Object-Manufacturing-LOM-10.png) Source: www.researchgate.net

Source: www.researchgate.netLaminated object manufacturing (lom) is an additive production technology that uses sheets of raw material. The method studied in this paper is laminated object manufacturing (lom).

Source: es.continuousdev.com

Source: es.continuousdev.comThe first lom fabrication system was developed in 1991 by helisys company. After each layer, the building platform is lowered and it is fed with new layer of material.

Source: www.whiteclouds.com

Source: www.whiteclouds.comThe software offsets the center path ofthe beam so as to cut a precise outline of each cross sections. The first commercial laminated object manufacturing (lom) system was shipped in 1991.

Source: www.custommade.com

Source: www.custommade.comLaminated object manufacturing (lom) is a method of 3d printing. Hagedorn, in laser additive manufacturing, 2017 6.3.1.4 laminated object manufacturing.

Source: www.researchgate.net

Source: www.researchgate.netThe first lom fabrication system was developed in 1991 by helisys company. The laminated object manufacturing or lom is the manufacturing process of making flat components by laying the thin layers or glued.

Source: www.researchgate.net

Source: www.researchgate.netThe material usually used are paper, plastic or metal foil. The first commercial laminated object manufacturing (lom) system was shipped in 1991.

Source: pick3dprinter.com

Source: pick3dprinter.comLayers of paper, plastic, or metal laminates are coated in adhesive, glued. The laminated objects manufacturing 1.

Source: www.desertcart.co.zw

Source: www.desertcart.co.zwLaminated object manufacturing (lom) laminated object manufacturing machine works by actually cutting the slices of the object out of a sheet of paper foil and then bonding them. Printers use this technology to.

Source: www.youtube.com

Source: www.youtube.comWhich of the following are problems with the current rapid prototyping and additivemanufacturing technologies? Layers of paper, plastic, or metal laminates are coated in adhesive, glued.

Source: www.slideserve.com

Source: www.slideserve.comIn it, layers of paper, plastic, or metal laminates are successively. Laminated object manufacturing (lom) is a rapid prototyping system.

It is used to create low cost 3d model using laser. The material usually used are paper, plastic or metal foil.

Source: pick3dprinter.com

Source: pick3dprinter.comLom allows for additively building parts by stacking subsequent layers of a material sheets on. After each layer, the building platform is lowered and it is fed with new layer of material.

More articles :

- hardwood flooring indiana pahardwood flooring indiana pa 3

- Living Room Wooden Floor Tiles

- floor and decor app

- flor decora%C3%A7%C3%A3o de casamento na praia

- wood flooring at floor and decor

- lifeproof stair treads

- dyson hardwood floor attachment v8

- oak laminate for flooring

- mayflower wood flooring reviews

- hardwood floor marker home depot

.png?_=170fe997dc8)